Important Terms You Need To Know About Machine Embroidery

Table Of Content

- Most Common Terms Used in Embroidery

- 1. Embroidery Hoop

- 2. Stabilizer

- 3. Embroidery Thread

- 4. Design File

- 5. Digitizing

- 6. Fill Stitch

- 7. Satin Stitch

- 8. Underlay Stitch

- 9. Jump Stitch

- 10. Tension

- 11. Appliqué

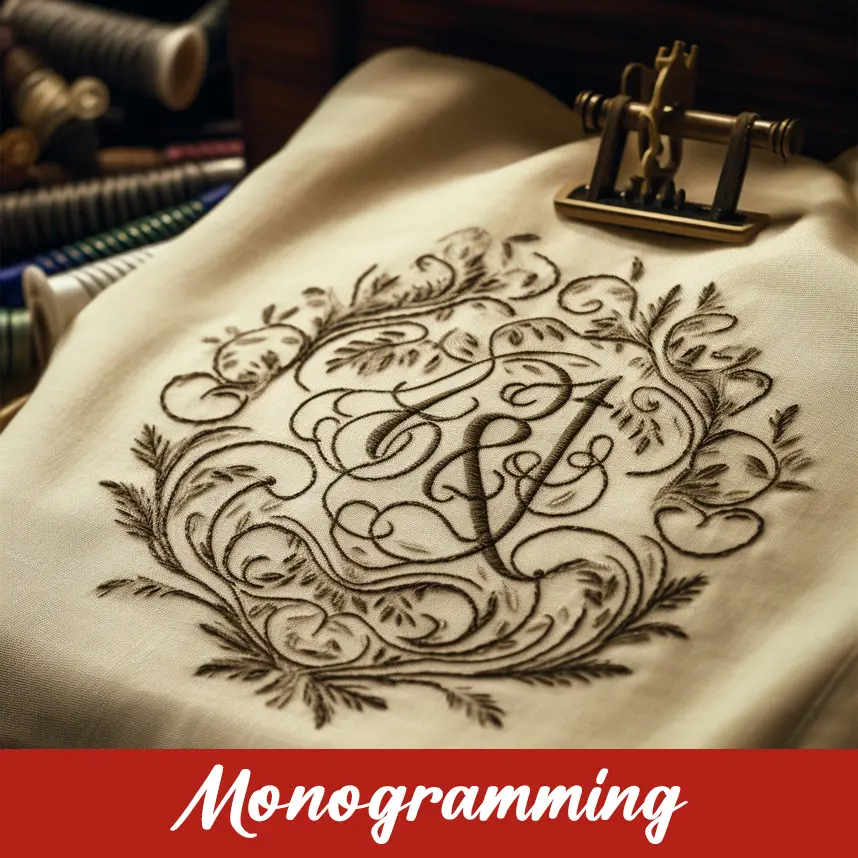

- 12. Monogramming

- 13. Thread Break

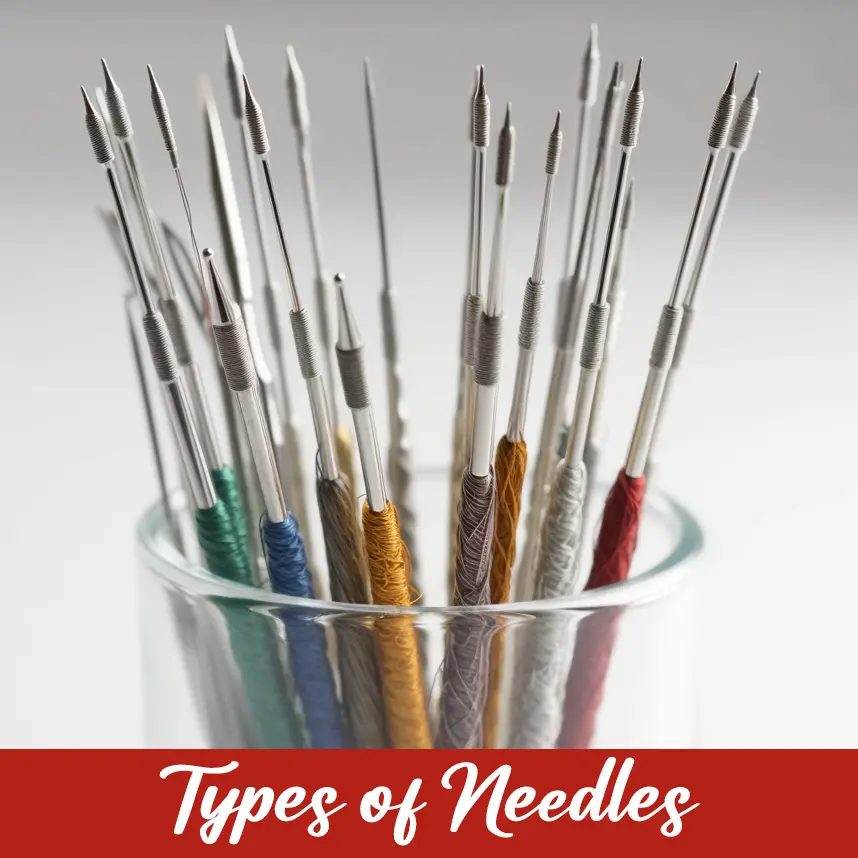

- 14. Types of Needles

- 15. Backstitching

- 16. Floating

- 17. Embroidery Machine Formats

- 18. 3D Puff Embroidery

- 19. Density

- 20. Multi-Needle Machine

- 21. Puckering

- 22. Density

- 23. Machine Maintenance

- 24. Underlay stitch

- Conclusion

Machine embroidery is fascinating art comprising both creativity and technology for producing stunning designs on fabric. Whether you’re a beginner or an experienced embroiderer, understanding the terminology is essential. Here are some of the most important terms to know:

Most Common Terms Used in Embroidery

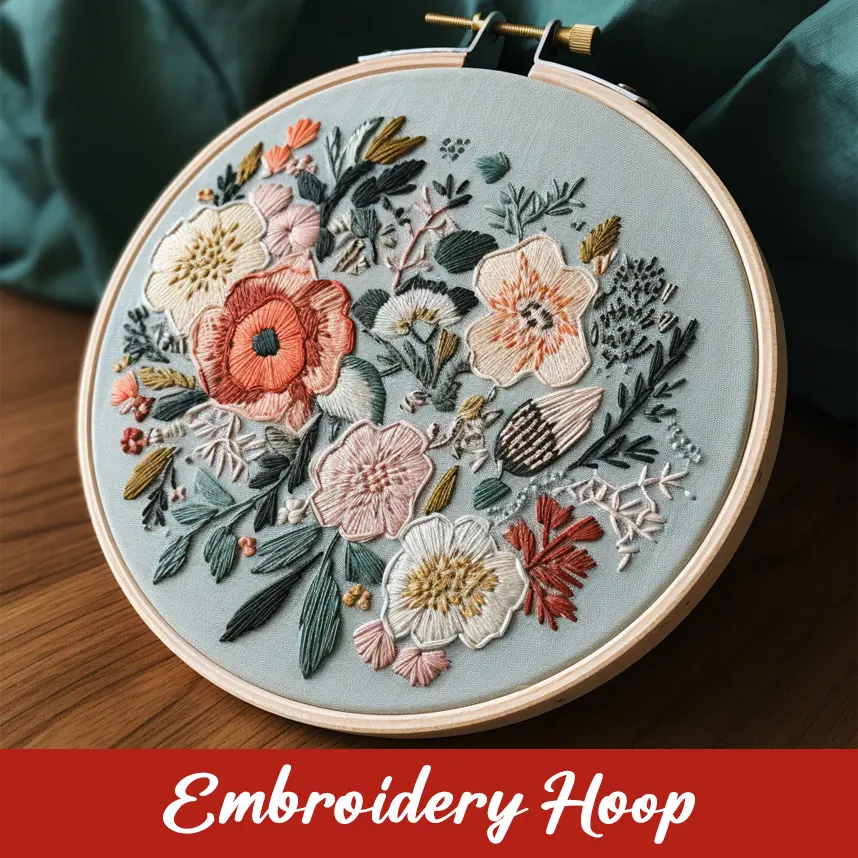

1. Embroidery Hoop

An embroidery hoop is a frame that keeps the fabric taut as the machine stitches the design. Hoops are available in a range of sizes to suit specific project requirements.

2. Stabilizer

Stabilizers help stabilize the fabric while embroidering. They keep the fabric from puckering or shifting, making sure the stitching is clean and accurate. Common types include:

Cut-away Stabilizer: Great for stretchy or fragile fabrics.

Tear-away Stabilizer: Easy to remove after stitching.

Flush-Away Stabilizer: Dissolves in water; good for sheer fabrics.

3. Embroidery Thread

Special embroidery threads made from polyester, rayon, and even cotton. They are robust and colourfast and great for professional-looking designs.

4. Design File

This is the digital pattern loaded into the embroidery machine. Common file formats include PES, DST, and JEF. Each machine brand requires different file types.

5. Digitizing

It involves turning a piece of art into an embroidery file digitally. This can be done through the mapping out of stitches, colors, and sequences for the machine to trace along.

6. Fill Stitch

These are densely close stitches that are stitched in to fill larger areas within a design. Fill stitches help create textures in embroidery, thus often utilized in solid shapes or backgrounds.

7. Satin Stitch

A smooth, shiny stitch generally used for lettering and outlines. It is very ideal for a polished, professional finish.

8. Underlay Stitch

Underlays are foundation stitches laid at the bottom for stabilization of the fabric so it would not distort. Underlay stitches are of prime importance for clean precise embroidery.

9. Jump Stitch

A thread movement between different sections of a design without stitching. Such threads are generally trimmed after finishing embroidery.

10. Tension

Thread tension: the balance of top thread to bobbin thread. Tension that is correct allows stitching to be smooth and free from loops or puckering.

11. Appliqué

Appliqué is a technique where pieces of fabric are stitched onto a base fabric to create designs. It is great for adding dimension and saving thread.

12. Monogramming

Monogramming is the art of embroidering initials or combination of letters in decorative fonts. It is widely used for personalizing items.

13. Thread Break

A thread break is the terminology used when a thread snaps at the time of stitching. It could be due to incorrect tension, poor-quality threads, or defects in the needles.

14. Types of Needles

Embroidery needles are made in many sizes and types for different fabrics and threads. Common ones include:

Sharp Needles-best suited for tight weaves.

Ballpoint- ideal for knits as they won't catch on the threads.

15. Backstitching

This is a stitch that overlaps to strengthen parts of the design as it tends to be stronger and will not unravel.

16. Floating

Adding more stabilizer underneath the hoop without holding it in the hoop. Floating is helpful for added support on finicky fabrics.

17. Embroidery Machine Formats

Every machine brand has different file formats that are supported. Some examples are:

Brother: PES ;Janome: JEF; Tajima: DST

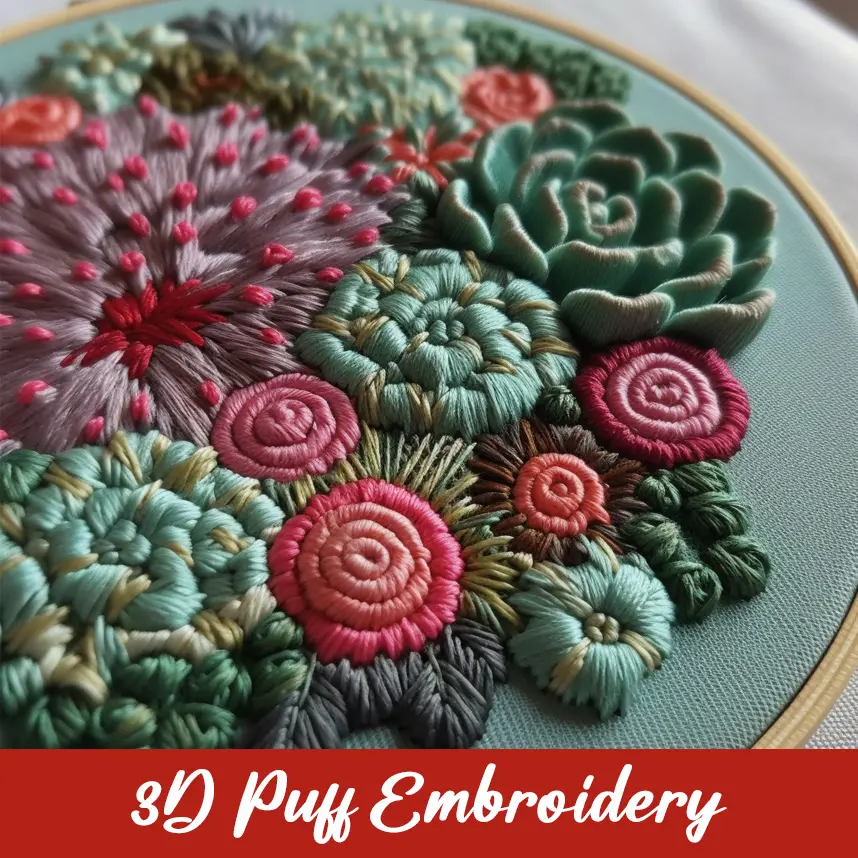

18. 3D Puff Embroidery

A method that employs foam under the stitches to create a raised, three-dimensional appearance. This is commonly used on caps and hats.

19. Density

The amount of thread in a specific area of the design. High density creates a solid look, while low density is used for lighter, airy effects.

20. Multi-Needle Machine

These machines have multiple needles, each threaded with a different color. They are ideal for complex designs and save time by reducing thread changes.

Pull compensation adjusts the width of stitches to accommodate fabric pull so that the design does not shrink or distort while embroidering.

21. Puckering

Puckering is wrinkles or distortion around the embroidery design. Proper hooping, stabilizing, and tension adjustment help prevent this issue.

22. Density

Density means the number of stitches in a space. Adjust density so that a design is neither too heavy on the fabric, nor too light.

23. Machine Maintenance

Maintenance, comprising cleaning, oiling, and the check for worn parts, assures your embroidery machine running smoothly and working out consistently every time.

24. Underlay stitch

The underlay stitches form the base of an embroidery design. These stitches are sewn below the visible design to provide stability, reduce puckering, and improve overall appearance.

Conclusion

In conclusion, in the field of embroidery digitizing, learning these terms will help you in understanding the aspects of machine embroidery. Whether you’re creating custom apparel, home decor, or gifts, understanding the language of embroidery is the first step to mastering this creative craft!