Magic of 3D Embroidery on PVC keychains

What are PVC keychains?

As the time passes quicker and faster the fashion trends of the people also change drastically. Where it is a clothing industry or hand-held items. As we all witnessed the fancy trends of keychains which were made of plastic material or whether it was made of metals. Those old styles of keychains are now outdated and old-fashioned.

Now it’s time to grab the trendy kinds of keychains which made a loud, trendy and funky statement in itself.

Now it is all about PVC keychains made by polyvinyl chloride martials. Which can be taken any shape you want because it can be moulded easily. Although the PVC keychain can be used in multiple ways like general purpose, add more coolness in personality and for promotional giveaways as well.

Kinds of PVC manufacturing

There are 2 types of manufacturing held for the PVC keychains:

Manual Dispenser

It is used for small-scale business or small unit production or a start-up. If the orders aren’t much in numbers and you are having limited quantities of moulds then the manual option is better.

Mechanical dispenser

It is used for the larger scale production and mass scaling orders. The mechanical dispenser is brilliant in speed and accuracy.

Solution used for stick the patch

There are quiet solutions or gluey material used to patch the embroidery. Some of them are following:

Sure bonder 725 Infinity Bond for $40

Fabric Hot Glue Stick for $8

Both are great at their own places, and both the glues can be used by small- & large-scale businesses.

Making of PVC Keychain

The mechanism of making a PVC keychain, the customer can select its desired shape, size and design of it. You can also put the logo of your design and desired area as well.

A logo or symbol can contain any kind of information; whether its name, date, email, phrase and image as well. In front of PVC the area is bigger. So, we have a larger area for displaying any type of customized message.

As more options have been opened for the back side as well so we can customize it at our will. The choices available are following below:

· Simple/plain back

· Text or any info at back

· Rubber at the back

Simple Back

It’s a simple plain back of the PVC keychain with no information at it.

Texting Back

Some information has been embedded at the back side to have it.

Rubber Back

You want to walk-in-style then the back side of PVC with rubber material it will cherry on the top.

After agreeing on all the points; logo, shape, size and text of your customized PVC keychains. You can send it to the digitizer or manufacturer for its making.

After sending or emailing the designer the manufacturer or digitizer will ask for any final changes or customization. Before the production process starts the digitizer will send a sample of it.

Roles of Manufacturing Process of PVC

Start-up Process

The keychains will first be moulded by the material through machines or hands. The molding and carving is done after the approval of final artwork. After the process the molds will be processed through harsh blasting and plating.

Rubber Glue Colour

The material which is used for making customized PVC keychains looks half-thin; it has to rhyme with the colour/pigment as the customer wished. After pigmentation the rubber has been put in a vacuum tube for eliminating the remaining bubbles for the perfect rubber surface.

Injection Process

The rubber glue will be injected if the mold and rubber material are ready. If the brand or label is plain then it will be done easily by machines. But the convoluted ones will be done by human hands as it will be preferred.

Scorching of rubber

For making the rubber good enough you have to baked the rubber for good quality PVC material. To do that thing you have to take the half-finished customize PVC and put it in the rubber oven machine and provide heating and hold it for only a minute. But, rerun it several times.

Rally & Parcel

The manufacturer starts to rally the keychains by sticking metal rings or chains after the rubber slot is ready. The makers made the final review and probe, checked out the quality of the product and then finally dispatched the items or orders for delivery.

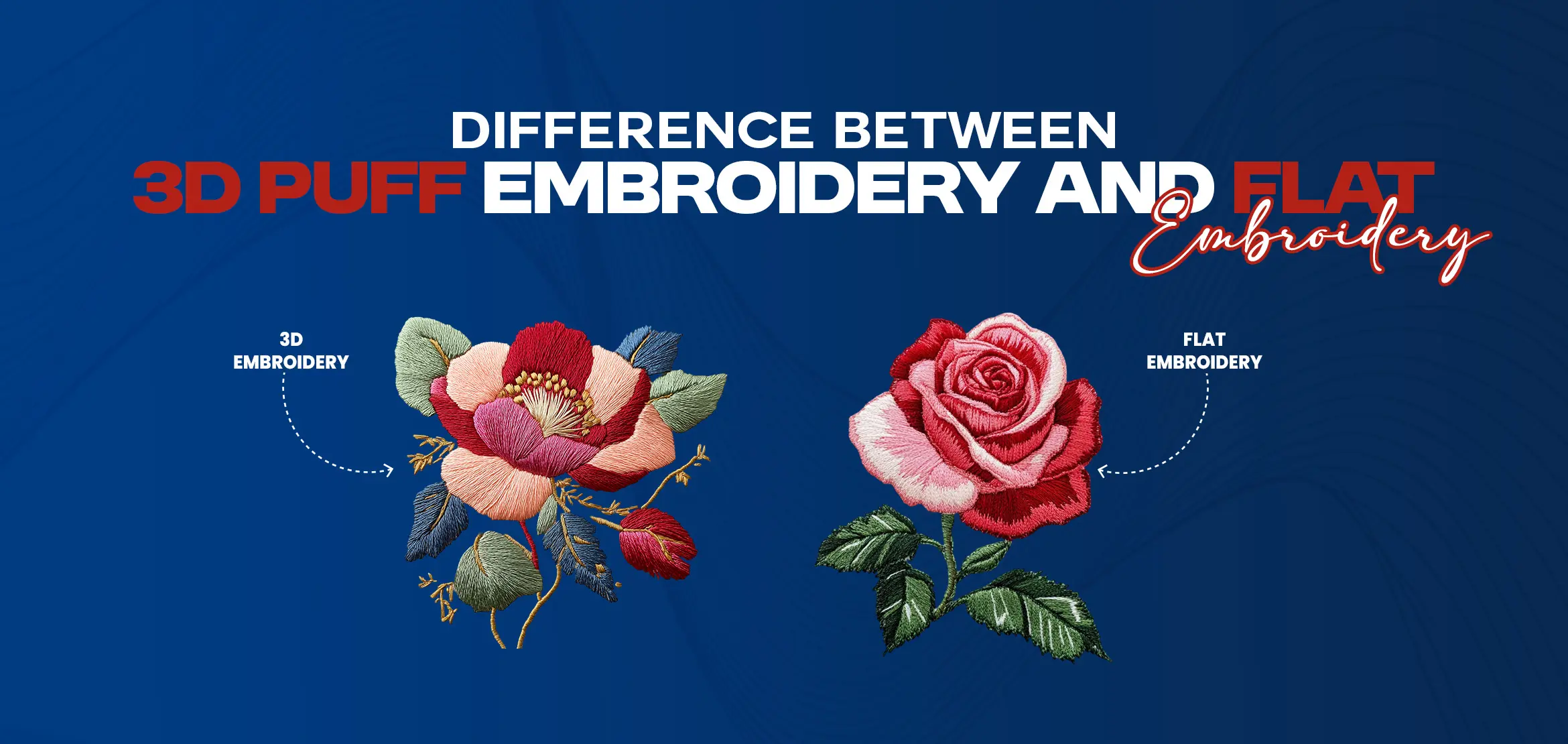

3D embroidery design on PVC

3D embroidery is now making a mark in the digitizing world and this method is used on the PVC made keychains as well. The PVC material keychains are standalone because of their durability, sustainability and they can be customized easily.

The 3D embroidery puff can be made with precise and detailing the design with the space so it can be done easily.

Methods for attaching the 3D material on PVC

First use the adhesive or resin to absorb the 3D printed object on the PVC surface. The PVC surface should also be flat and clean for the embroidery hoop as it will taut it.

Stabilizer for 3D Embroidery

Use the ideal stabilizer for the embroidery. As it will hold the stitches for more perfection.

Digitize the design

Digitized the foam type of puff by the embroidery software or pre-digital designed for puff foam. Make sure the foam should be thick and clear for better results. So that the stitch can be done by thread embroidery before.

Starts 3D Embroidery

Put the PVC and stabilizer on the embroidery machine. Start embroidery and then the outer area of design will stitch-up. Then foam will be compressed and will give it a puffing effect. After finishing the 3D Embroidery cut the extra thread and foam to make it look good.