What is a Hat Embroidery Machine?

Table Of Content

- History and Evaluation of Hat Embroidery Machines

- What is the Main Purpose of a Hat Embroidery Machine?

- How Does Hat Embroidery Machine Work?

- Step1:

- Choose the Right Design Selection

- Step 2:

- Hooping the Hat

- Step 3:

- Stitching the Design

- Step 4:

- Finalizing the Design

- What Type of Embroidery Machine Do You Need for Hats?

- Top 6 Embroidery Machines in 2024 You Need to Know

- Brother PE800

- Janome MB-7

- Melco EMT16X

- Brother PR-1050X

- Ricoma RCM-1501TC

- Juki Tajima Sai

- FAQ’s

A hat embroidery machine is known for its designed machine to stitch custom designs onto your hats. No matter if you are a student, an entrepreneur, or have another profession. Hat embroidery machines make your life easy and you can customize your own designs and add logos, text, or other elements. By the way, there are different types of headwear like beanies, caps, and visors. So you can customize any headwear.

Hat embroidery machines are different from other sewing machines. You can not design any headwear with a regular embroidery machine. Hat embroidery machines make professional and high-quality designs and create unique and distinctive designs.

If you are thinking about starting your business but are confused about how to start, so let me tell you first the essentials for the hat embroidery and machine. This blog post will cover everything from basic to advanced features, types, functions, best embroidery machines in 2024, and how hat embroidery machine works. so let's start the blog.

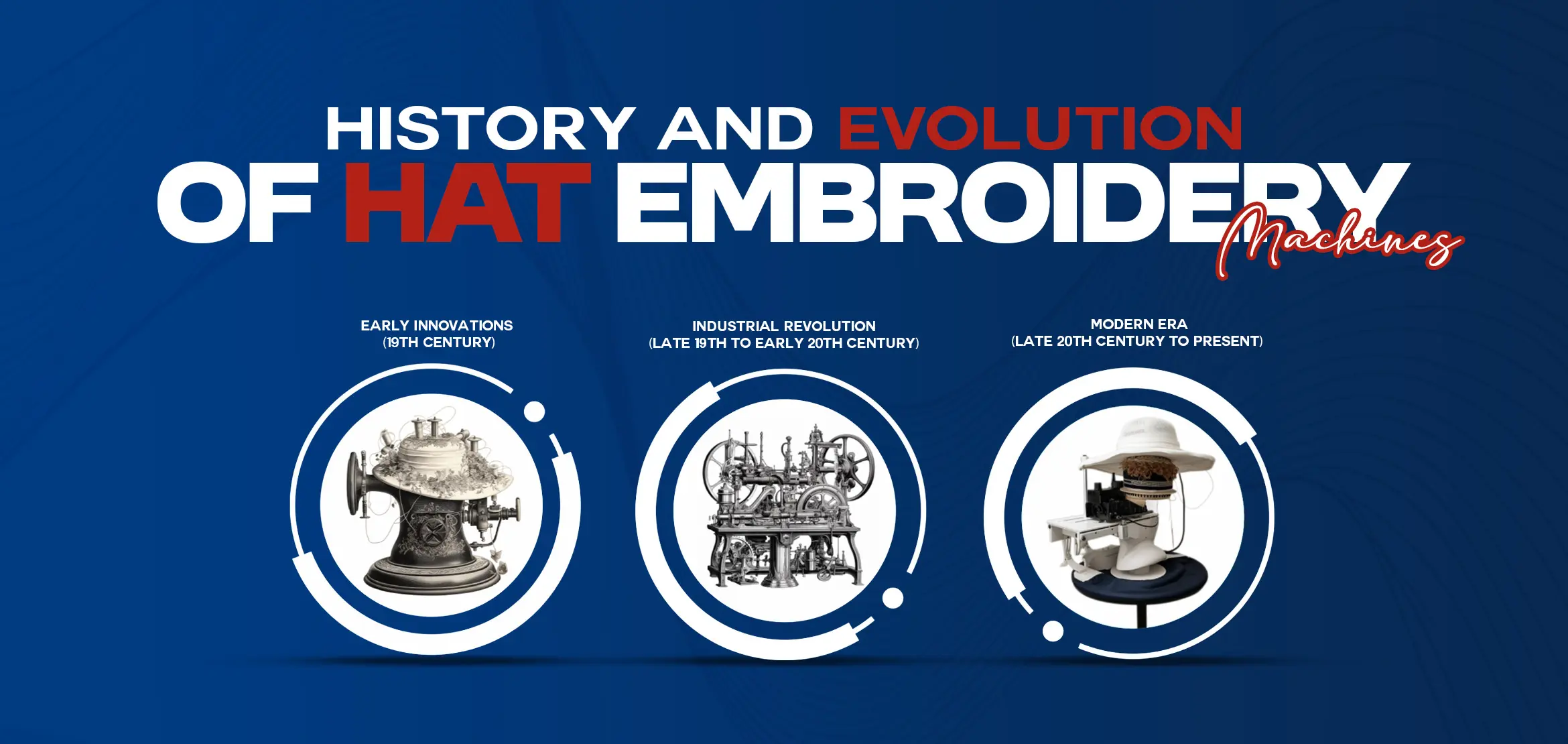

History and Evaluation of Hat Embroidery Machines

Embroidery has been an ancient and traditional culture for thousands of years. But the process of the hat embroidery machine is new. In the ancient age, embroidery machines were used manually and required high skills to maintain quality and accuracy, but now, with the advancement of technology, machines are becoming automated, and making the way for modern and trendy embroidery designs.

Hat embroidery machines have advanced a long way since they were first invented. At first, machines designed for plain fabrics were unable to handle the curved surfaces of hats. This evolved with the invention of customized cap frames that hold caps perfectly in accurate place, and give embroidery at difficult angles. Machines were invented over time, becoming more accurate, quicker, and easy to use.

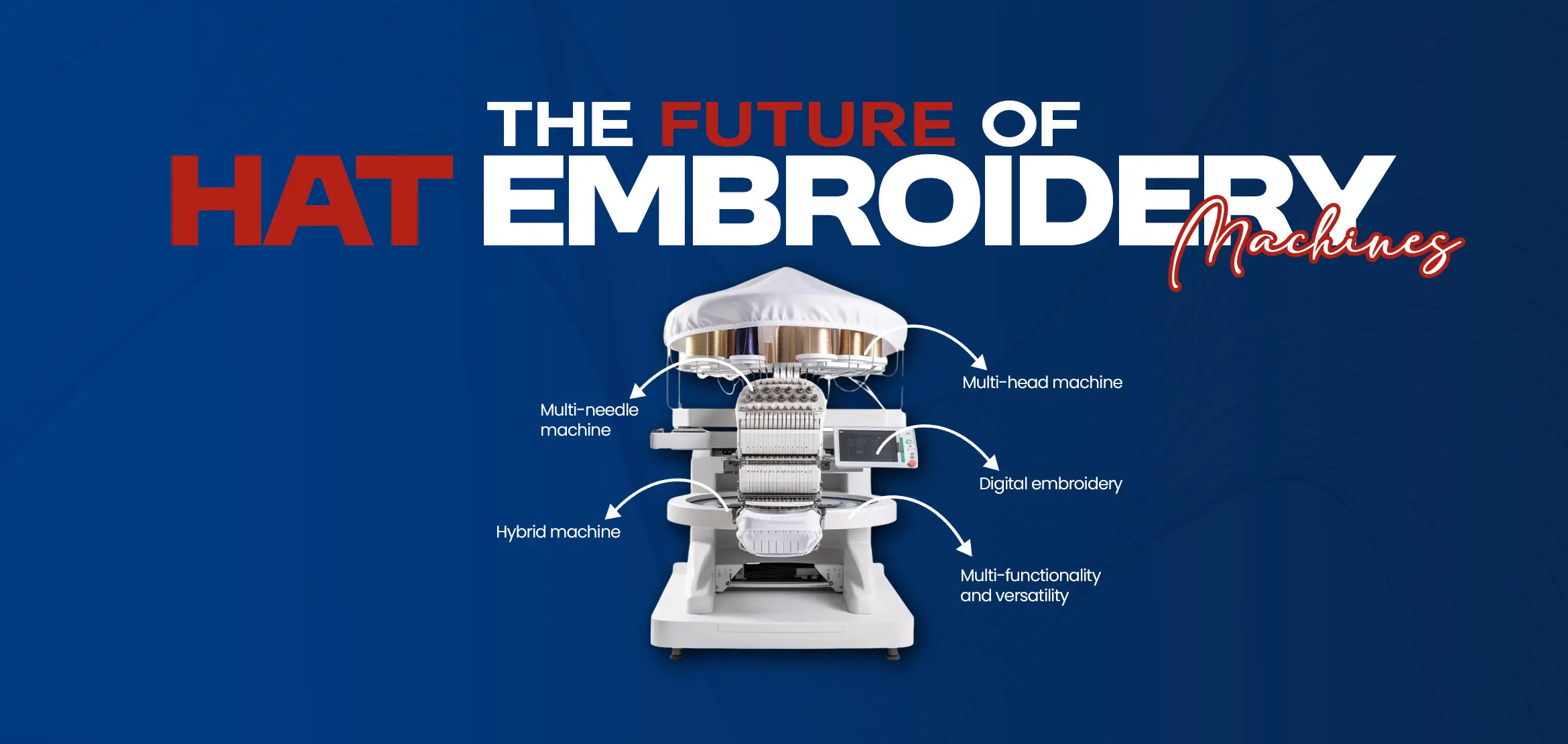

New machines consist of digital design input, multiple needles for quick thread changes, and more versatility, making it easy to make top-quality, custom hats embroidery designs in just a few hours.

What is the Main Purpose of a Hat Embroidery Machine?

The main purpose of a hat embroidery machine is to enable accurate and long-lasting embroidery on the rounded and curved surfaces of hats. This is particularly helpful for businesses and beginners who make unique hats for customers, sports events, or for marketing purposes. These machines ensure that designs, like logos, letters, or intricate patterns, are embroidered accurately, giving a high-quality finish.

I remember using a regular embroidery machine to stitch hats, which frequently led to uneven or bunched-up fabric, then I realized having an advanced hat embroidery machine is a game changer. It is especially intended for the task and performs it much more efficiently.

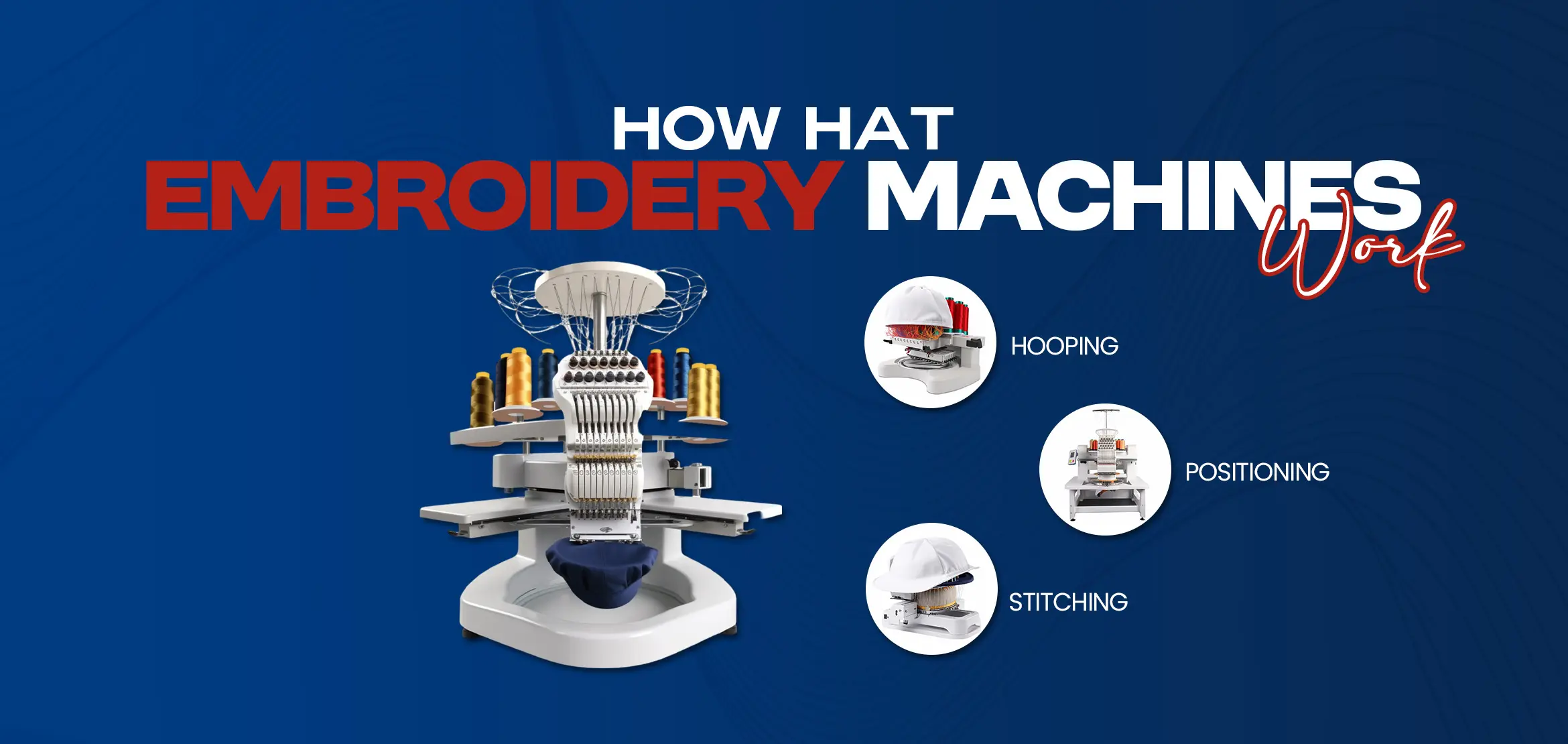

How Does Hat Embroidery Machine Work?

A hat embroidery machine works similarly to a regular embroidery machine but includes specialized features to handle the unique challenges of embroidering on curved surfaces, like the front panels of a cap. Here’s a quick breakdown of how it operates:

A custom hat embroidery machine and a regular embroidery machine are similar but add new and some advanced features to a custom had embroidery machine to handle specific issues of embroidery designing on curved surfaces. For example: the text on the cap and more. Here is a quick and easy step of machine work.

Step1:

Choose the Right Design Selection

.webp)

Use embroidery software to create or digitize the design you want. if you want the best results, choose Digitizing USA. we convert any image into an embroidered file that is the best for custom hat embroidery. We fulfill your demands.

Step 2:

Hooping the Hat

.webp)

Unlike plain garments, hats need special frames, commonly referred to as "cap frames," to keep them in the right place while the machine stitches. These frames hold the cloth tight and set properly.

Step 3:

Stitching the Design

.webp)

When the hat is properly hooped, the machine embroiders the design on the curved surface. The machine's multi-needle process changes colors automatically, following the pattern specified in the digital design.

Step 4:

Finalizing the Design

.webp)

Once the stitching is completed, the hat is gently removed from the frame, cut, and checked for quality. Any loose threads are cleaned up, and the design is checked for accuracy.

Hat embroidery machines are specifically designed to meet the specific requirements of caps, making the procedure quicker and more perfect than doing it by hand.

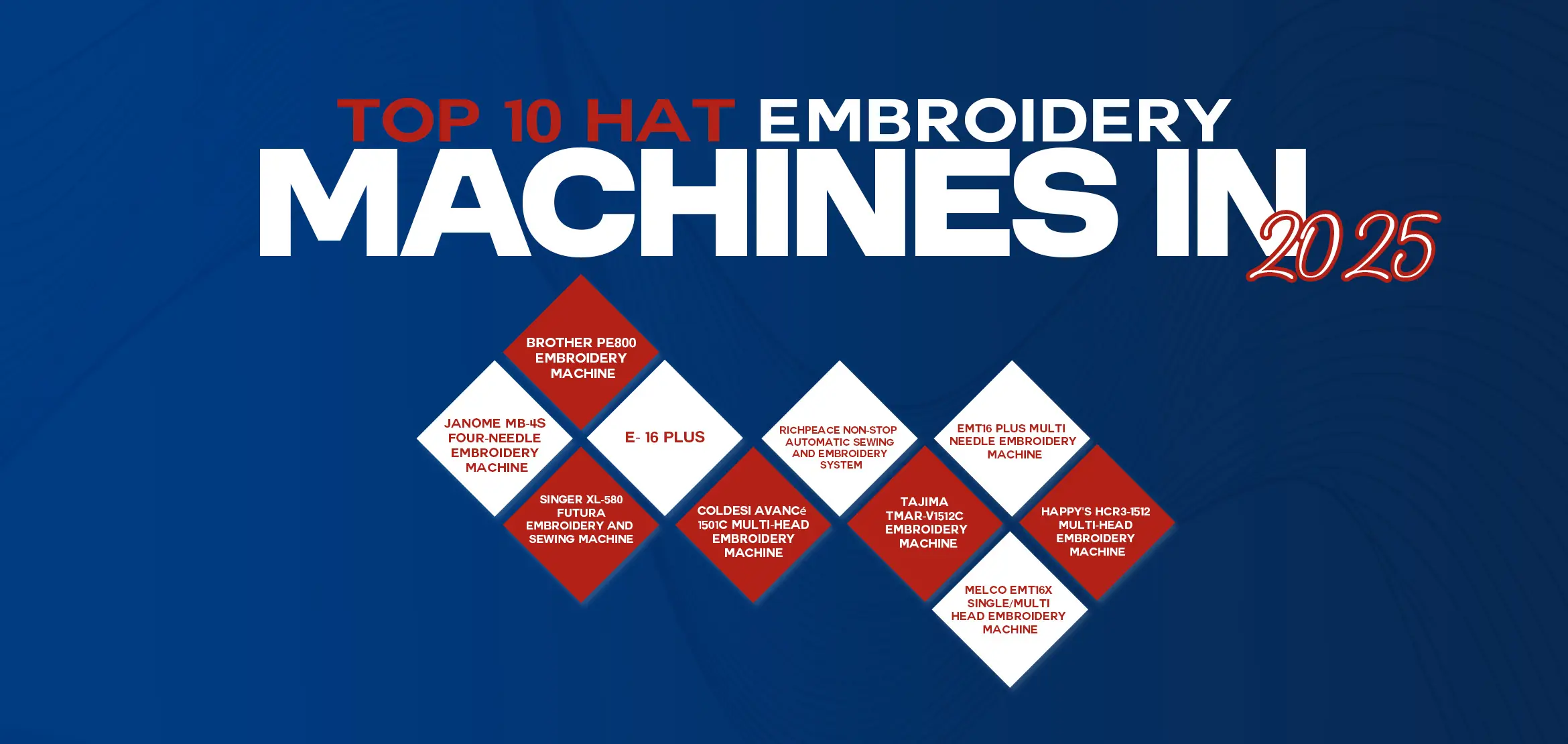

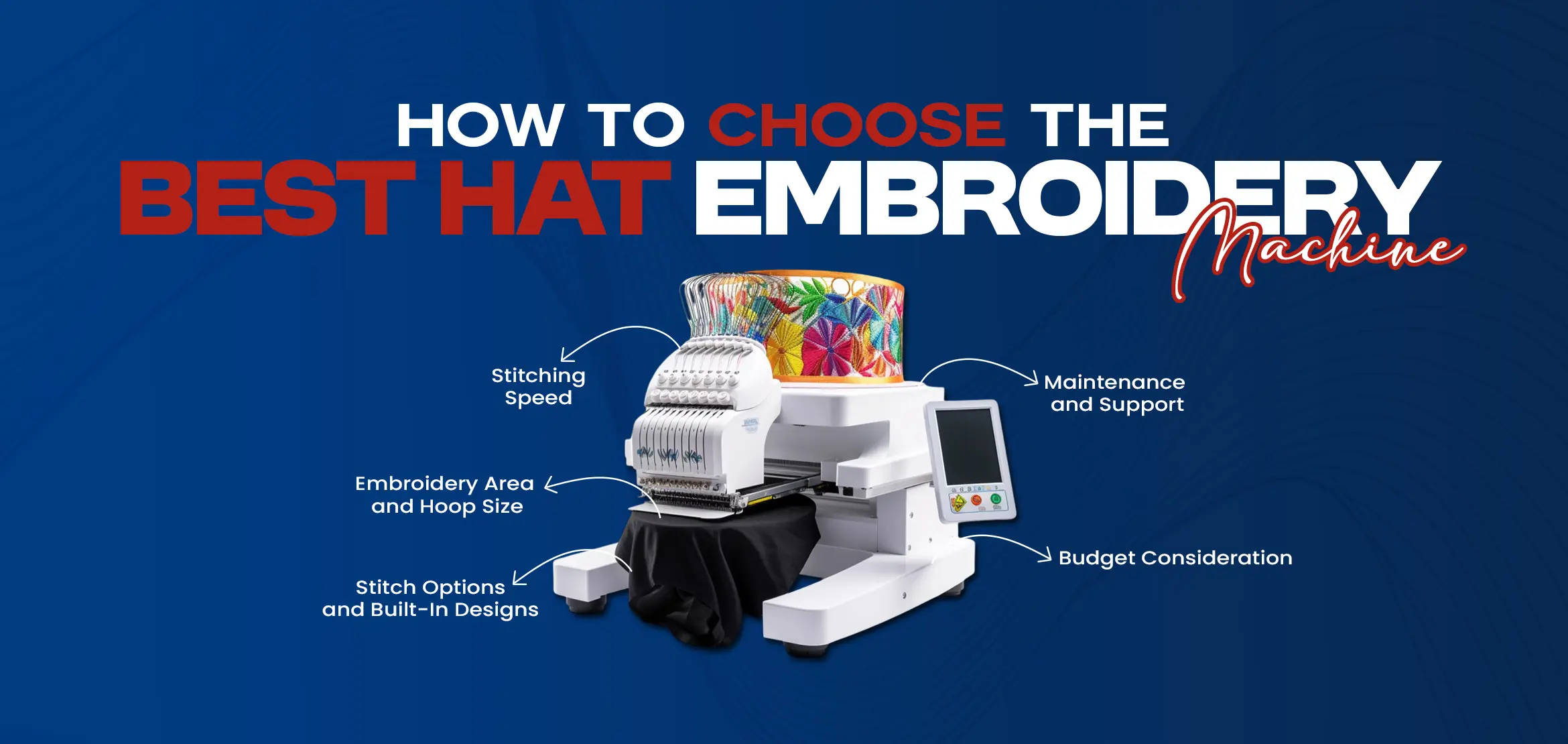

What Type of Embroidery Machine Do You Need for Hats?

Not all embroidery machines are suited for embroidering hats. To properly embroider on hats, you will require a machine with the following important features:

Cap Frame: This specific attachment helps the machine hold a hat while stitching.

Multi-Needle Capability: Machines that have multiple needles switch between colors without even manually changing threads, which speeds up the stitching process.

Wide Embroidery Field: A major working area that helps you create more complex designs, including those on curved surfaces.

Fast-Speed Function: Professional-grade machines usually offer quick stitching speeds, which reduces production time.

In my opinion, a machine like the Brother PE800 can be a better choice for small projects, on the other hand, advanced and experienced users might choose the Melco EMT16X, which is designed for commercial usage and specializes in handling caps and other curved fabrics. As you know choosing the right hat embroidery machine is important for delivering the highest quality custom designs. Here are the top 6 hat embroidery machines for 2024: This multi-needle machine is designed for experts. Its seven needles enable faster stitching and automated thread color changes, it would be great for customized hat embroidery. The Melco EMT16X is a major player in the embroidery industry and is commonly used in commercial settings. It is designed for speed and clarity, with the capability to handle enormous production values. Brother PR-1050X 10-needle machine, with a simple touchscreen display, would be the right choice for people who are for looking an appropriate balance of functionality and simplicity of use. This machine has 15 needles and is designed for speed and durability, making it good for companies that specialize in customized hats. Q1: What kind of needle do you use for hat embroidery? Ans: To get the best results, choose a sharp 75/11 needle for hat embroidery. Q2: What is the best thread for embroidery hats? Q3: Why do my needles keep breaking when embroidering hats? Ans: Needle breaking can be caused due to improper tension, inappropriate hooping, or using a needle that is too small for the fabrics. Q4: Can you embroider hats at home?Top 6 Embroidery Machines in 2024 You Need to Know

Brother PE800

.webp)

This single-needle machine is well-known for its simplicity and is suited for embroidery lovers and small businesses alike. It includes a hat hoop attachment, making it perfect for newbies.Janome MB-7

.webp)

Melco EMT16X

.webp)

Brother PR-1050X

.webp)

Ricoma RCM-1501TC

.webp)

Juki Tajima Sai

.webp)

FAQ’s

Ans: Polyester thread is best for hat embroidery because it is strong and durable to wear.

Ans: Embroidering a hat might be difficult for newbies because of its curved surface, but with the proper machine and practice, everything gets easier.

Q5: Is a hat embroidery business profitable?

Ans: Yes, a hat embroidery Business may be quite successful, especially when dealing with custom orders for events, companies, or fashion.