How to Choose the Best Hat Embroidery Machine

Are you on the hunt for the best hat embroidery machine but feeling overwhelmed by the plethora of options? You're not alone, and we're here to help. This comprehensive guide is designed to help you navigate the choices and find the top-notch machine that perfectly suits your needs.

Explore essential features and expert tips to find the perfect match for your hat embroidery projects.

Let's begin:

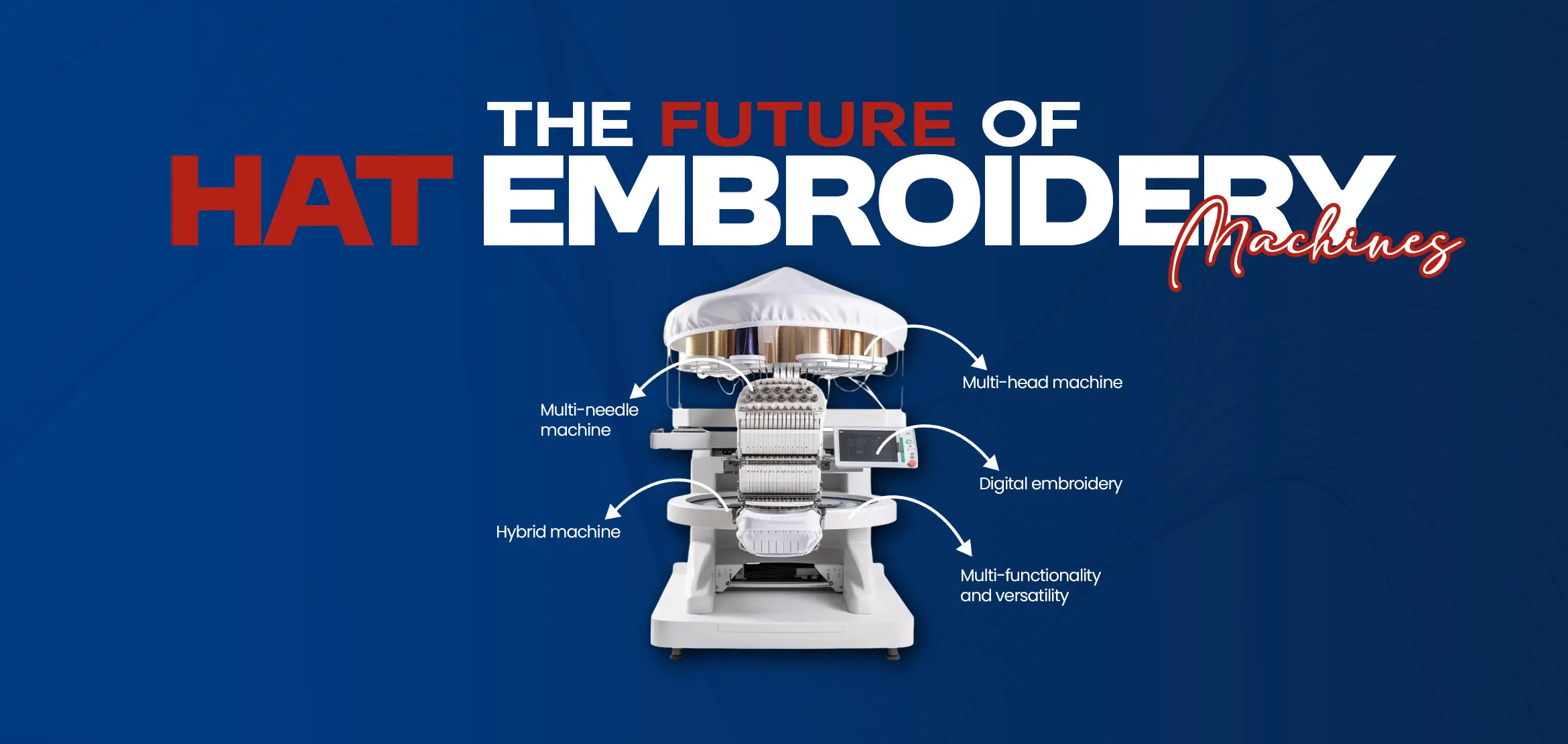

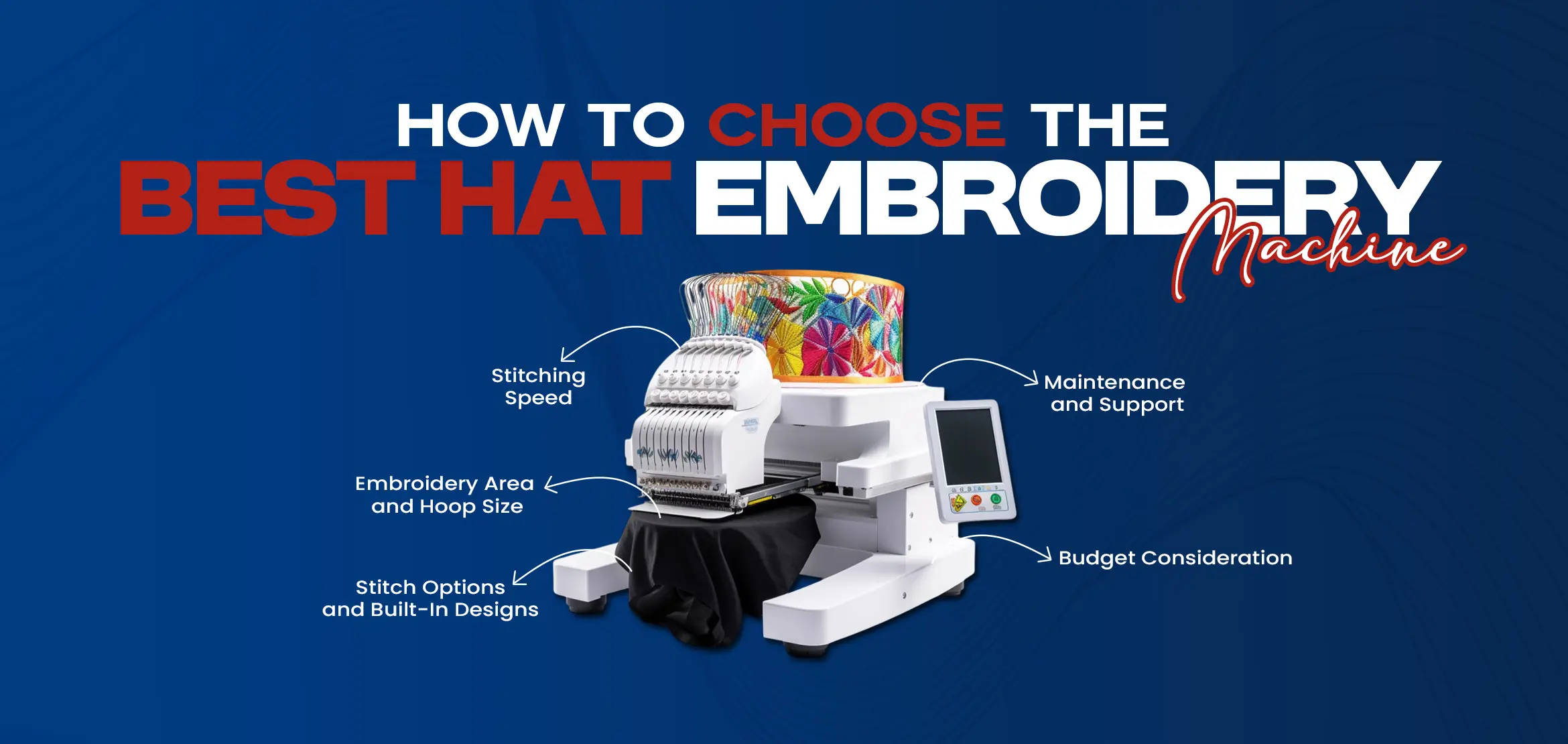

Key Factors to Look for While Choosing a Hat Embroidery Machine

This section helps you choose the right product:

1- Embroidery Area and Hoop Size

.webp)

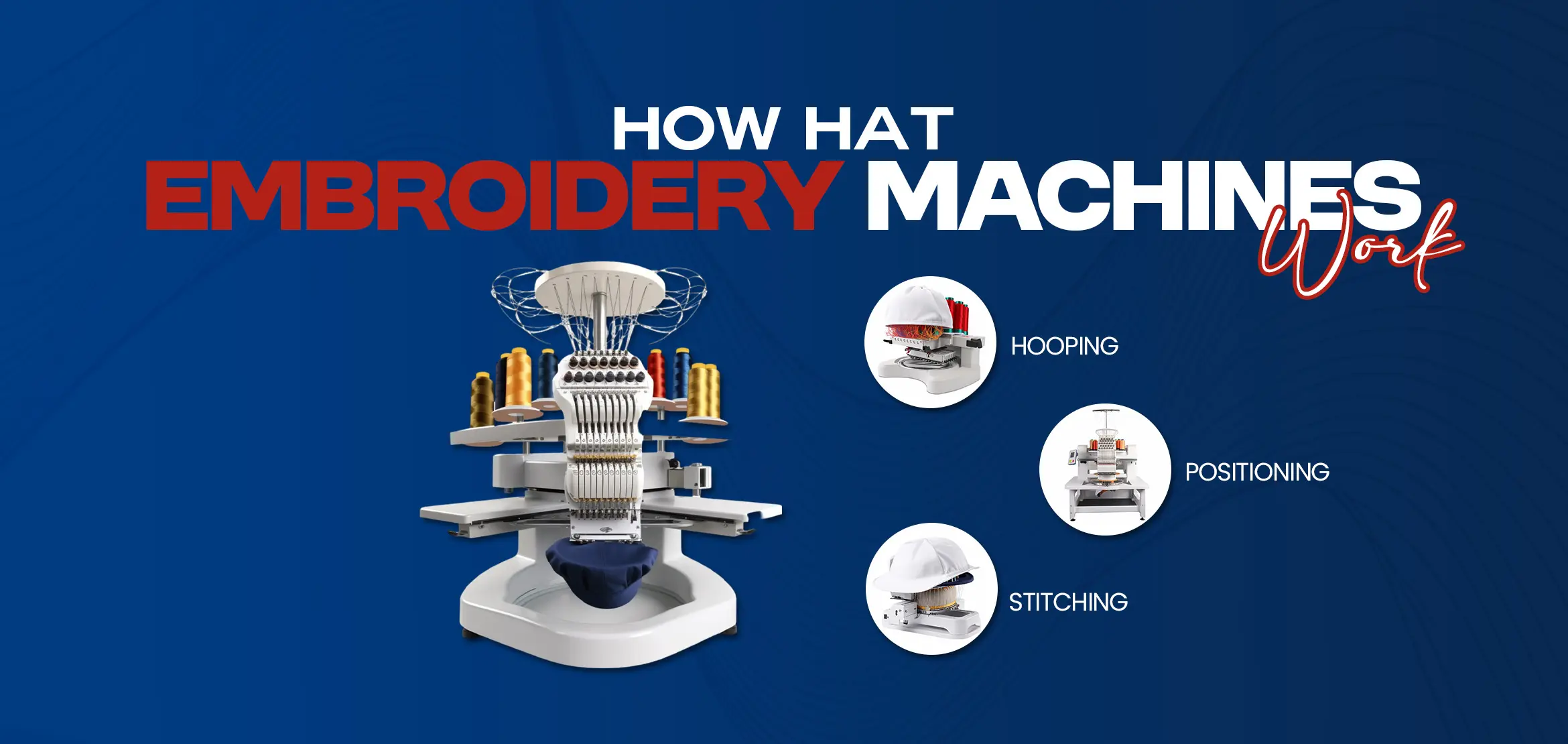

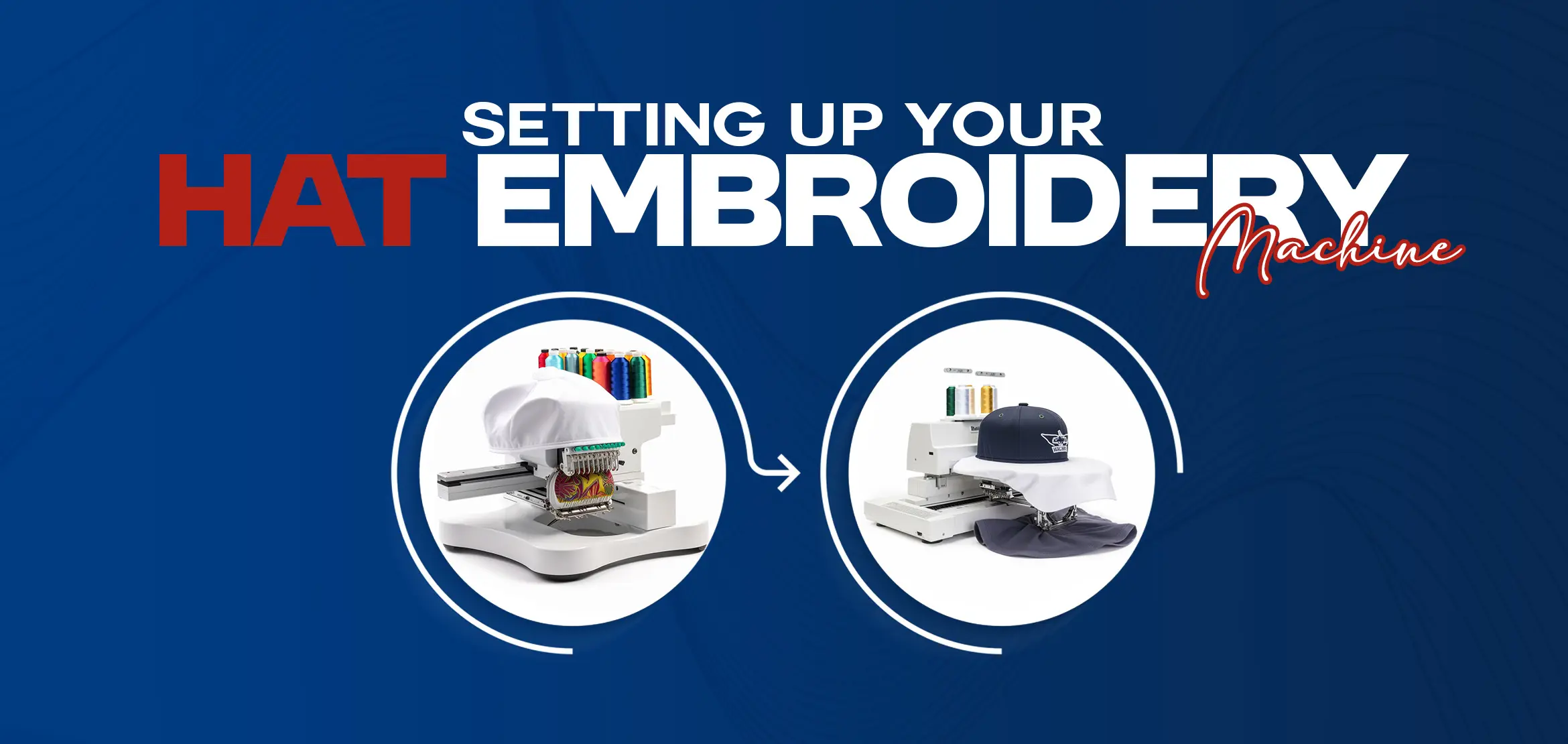

The maximum area the machine can stitch within is the embroidery area. You'll need a machine big enough to handle various designs regarding hats. More room for embroidery allows more freedom regarding different hat sizes and complex designs.

Hoop sizes that can be adjusted are essential for keeping caps firmly in place while stitching. Seek for machines made especially for hat embroidery with various hoop sizes. This guarantees that your designs will always be precisely aligned and produced

2- Stitching Speed

.webp)

Stitching Speed: Fast embroidery machines can finish patterns faster, particularly when handling large orders. Variable speed machines let you change the speed according to the material you're working with and the design complexity.

Automatic Features: Look for machines with automatic thread cutters, needle threaders, and color change choices. By reducing manual involvement and saving a significant amount of time, these features improve the efficiency of the embroidery process.

3- Maintenance and Support

.webp)

Look for a machine that is simple to maintain and clean. Routine maintenance is made more accessible on machines with replaceable parts, thread pathways, and accessible bobbin cases.

4- Essential Features to Look For

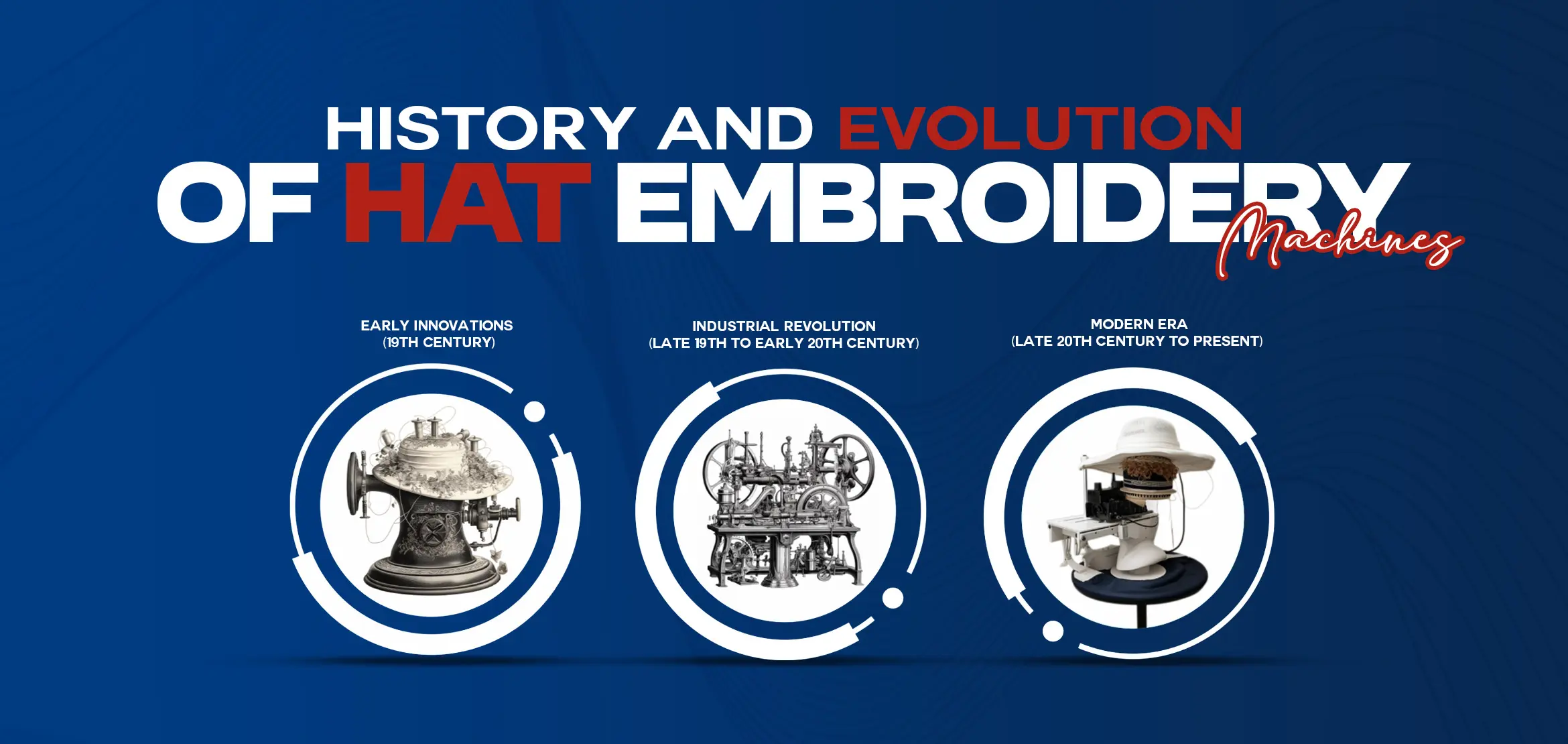

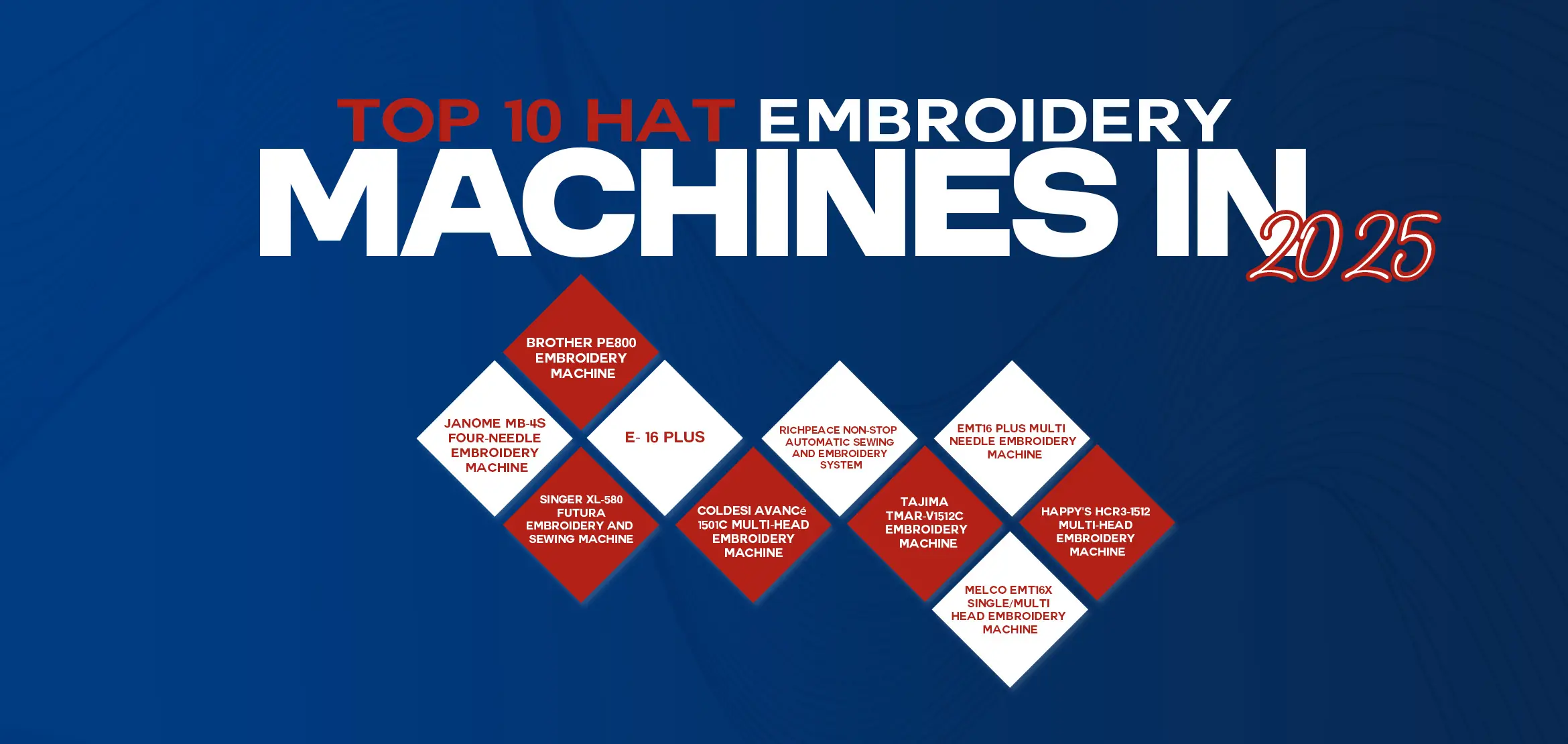

Upon assessing hat embroidery machines, a few essential elements should be your top priorities. Ensure the machine has a hat-designing hoop; larger hoops provide greater design flexibility. Using several thread colors without switching them out manually is crucial for efficiency when using multi-needle machines, which usually have six to ten needles. Choose a machine with a stitch per minute (SPM) rate of at least 800 because more excellent SPM rates translate into faster productivity. Touchscreens and integrated tutorials are user-friendly interfaces that can significantly improve your experience. Various methods of transferring designs, such as USB ports, Wi-Fi connectivity, or direct PC connections, should be available on modern workstations. The cost of embroidery machines can range from several hundred to several thousand dollars, making them a substantial investment. Think about your spending limit and factor in the software, maintenance, and accessories price. Entry-level machines are reasonably priced and have minimal functions, making them ideal for novices or enthusiasts on a tight budget. For dedicated hobbyists or small company owners, mid-range machines are perfect because they balance price and functionality. Large-scale production works well with high-end equipment with many needles, high speed, and complex features. Stitches such as satin, fill, and ornamental stitches are available on different embroidery machines. Every stitch type has a specific use. Thus, selecting a machine that can produce the stitch kinds your designs require is critical. Pre-made designs are helpful, particularly for novices. Using these pre-installed designs, you may start working more quickly and save time. Furthermore, importing custom designs is essential for producing one-of-a-kind and customized products. The ability to write letters is also crucial if you want to include text in your designs. Seek devices with a wide range of fonts and editing capabilities to alter the content as necessary. Faster manufacturing times and color changes are possible with multi-need devices. Automatic thread trimming is a helpful feature that saves time and minimizes manual labor, which trims the thread at the end of a stitch. Proper thread tension is vital for achieving high-quality stitches. Adjustable thread tension machines enable you to precisely alter the tension to suit various materials and threads, guaranteeing reliable and polished outcomes. As we discussed before, selecting the embroidery machine is a time-consuming task. You need to pay more attention to critical features that cost you heavily. To stave off any unintended consequences, take time, consider all factors, and then make a final decision. Embarking on your embroidery journey with a suitable machine will save you time and effort and elevate the quality of your work. Happy stitching!.webp)

5- Budget Consideration

.webp)

6- Stitch Options and Built-In Designs

.webp)

7- Color Capability

.webp)

Conclusion