Common Causes of Thread Breaks in Machine Embroidery and Solutions

Table Of Content

- Common Reasons for Thread Breaks

- Incorrect Threading

- Improper Thread Tension

- Damaged or Low-Quality Thread

- Incorrect Needle

- Bobbin Issues

- Fabric Movement and Hooping Problems

- Machine Maintenance Neglect

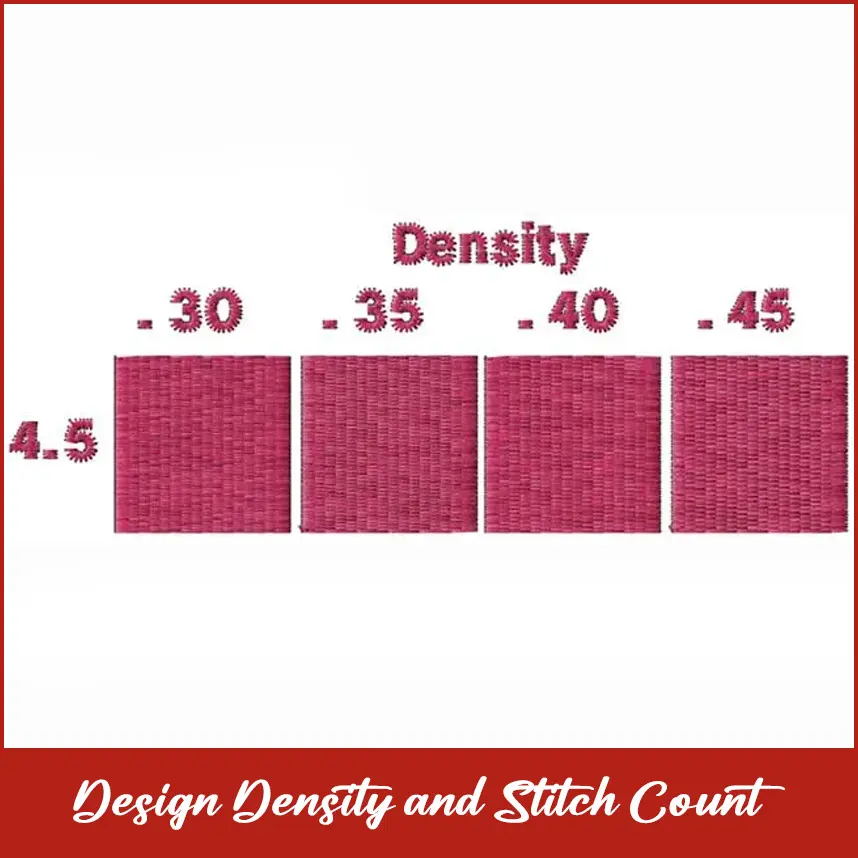

- Design Density and Stitch Count

- Machine Speed

- Practical Remedies to Resolve Thread Breaks

- Re-thread Carefully

- Adjust Thread Tension

- Use Quality Thread

- Choose the Right Needle

- Check your Bobbin

- Re-hoop Tightly

- Clean Your Machine Regularly

- Make Design Adjustments

- Slowing Down Stitching

- Preventive Tips to Reduce Thread Breaks

- Conclusion

- Reach to us for Professional Digitizing Services

- Frequently Asked Questions

- Why does my embroidery machine keep breaking the thread?

- What is the best way to adjust thread tension to avoid breaks?

- Can an embroidery design cause thread breaks?

- How often should I clean my embroidery machine to prevent thread breaks?

- What type of needle do I use to reduce thread breaks?

Are you annoyed by frequent thread breaks during machine embroidery? It is a typical pain point for new learners picking up the basics and intermediate users dealing with intricate designs. A thread break can halt your workflow, waste thread, and discourage you. Let's learn the typical issues behind these breaks and knowing how to fix them can greatly enhance your embroidery process. This guide will take you through the major reasons for thread breaking while embroidering and give you useful thread break solutions for home machine embroidery and more.

Common Reasons for Thread Breaks

There are a number of reasons why you may experience those annoying thread breaks in machine embroidery. Determining the underlying reason is the initial step towards an easier stitching experience.

Following are some of the most frequent issues:

Incorrect Threading

This is usually the first issue, particularly among novices. If the thread is not routed correctly through all the tension discs, guides, and the take-up lever, it may snap under tension.

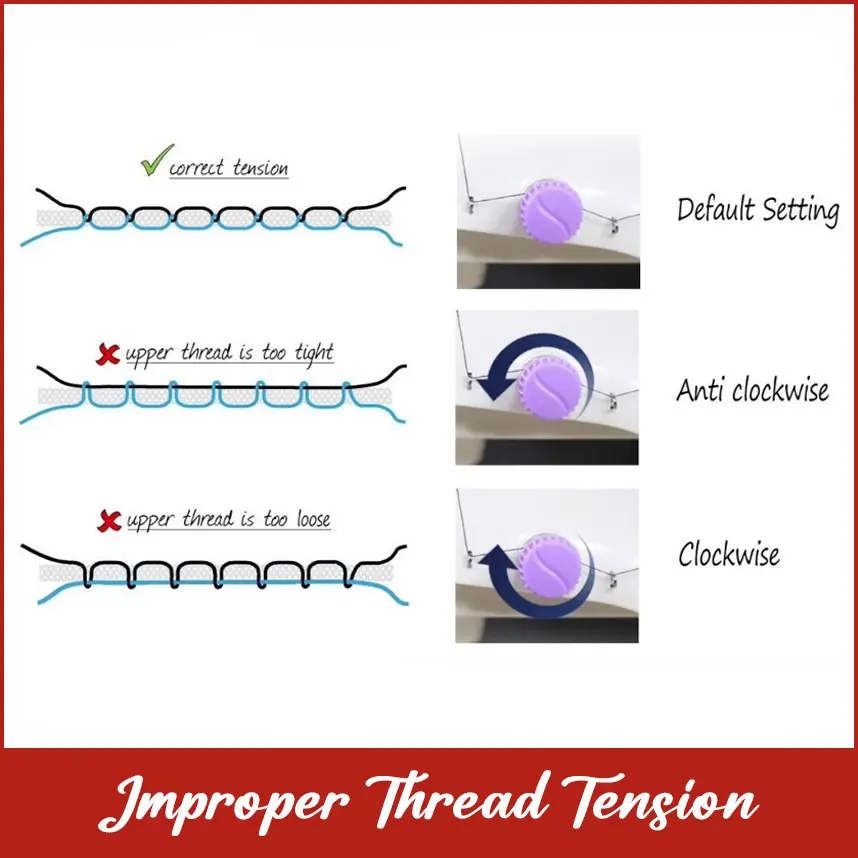

Improper Thread Tension

Too little or too much tension causes the embroidery thread to snap during design. Too tight tension exerts too much pressure on the thread, and loose tension results in looping and tangling that will ultimately result in a break. Understanding the ideal thread tension settings to prevent embroidery breaks is important.

Damaged or Low-Quality Thread

Old, frayed, or tangled thread is more likely to break. Likewise, using extremely thin or cheap thread for tight designs can be problematic.

Incorrect Needle

Working with the wrong kind or size of needle for your fabric and thread can produce too much friction and result in thread breaks during machine embroidery. A dull or bent needle can also catch on the thread.

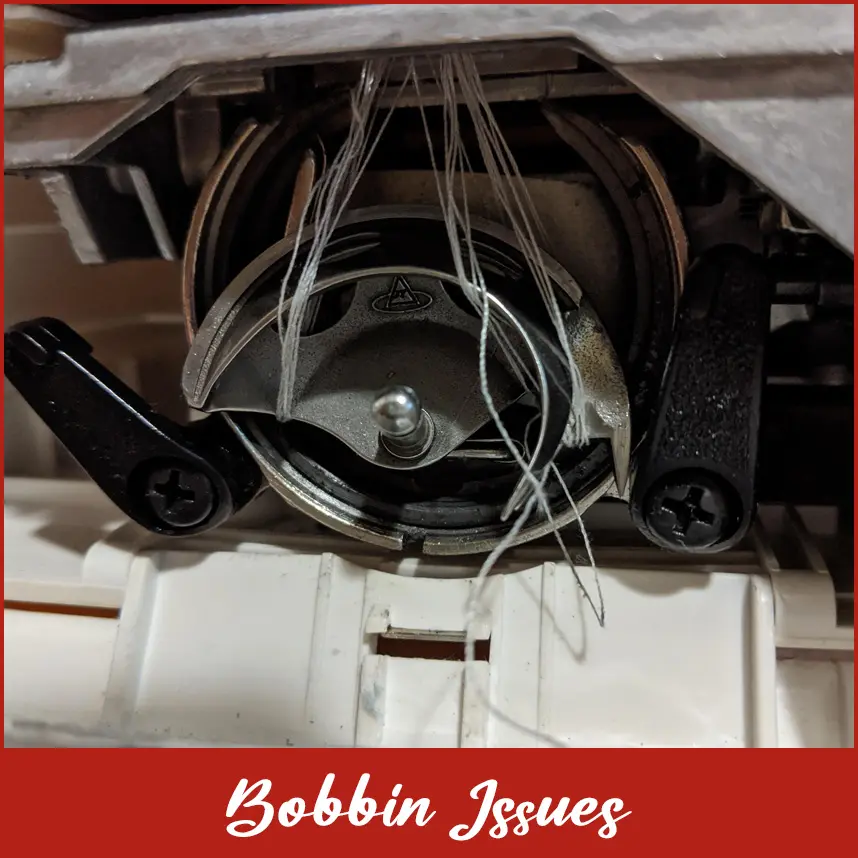

Bobbin Issues

An improperly wound bobbin, a bobbin inserted incorrectly, or a bobbin case with incorrect tension can all contribute to thread breaks. Tangled thread in the bobbin area is a frequent cause.

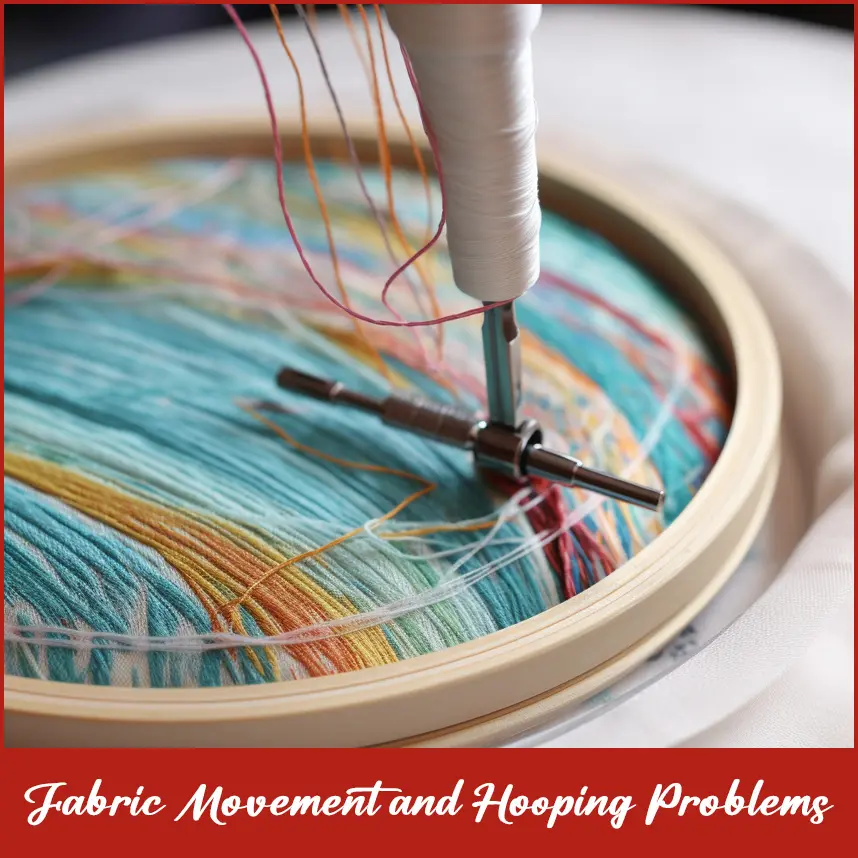

Fabric Movement and Hooping Problems

If your fabric isn't hooped tightly and securely, it can shift during stitching. This movement can pull on the thread unevenly, leading to breaks.

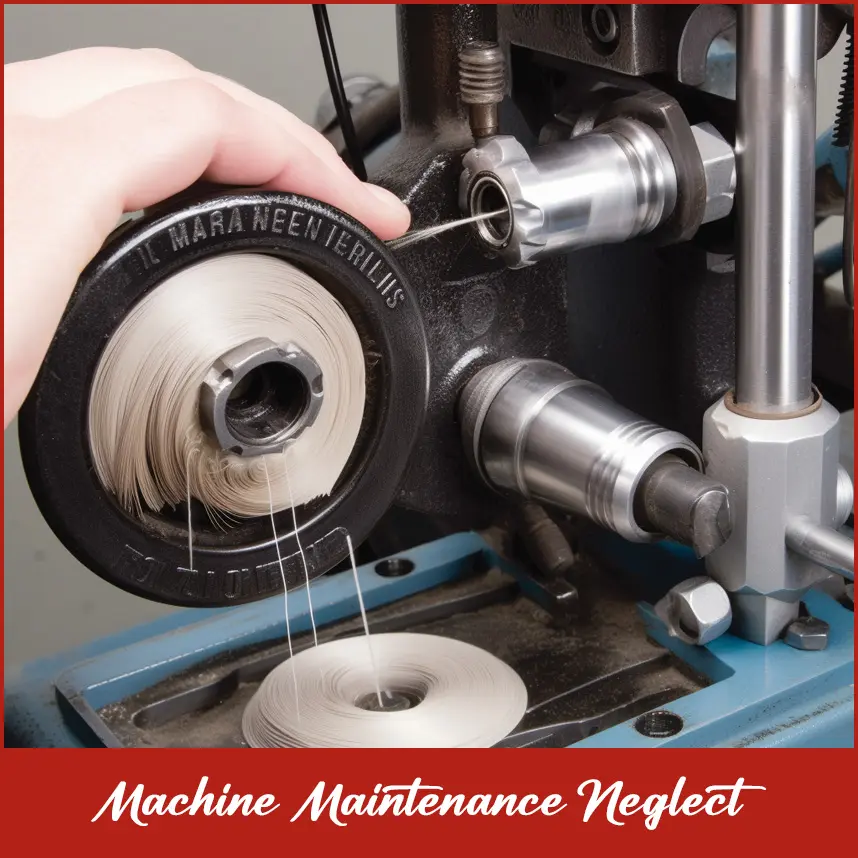

Machine Maintenance Neglect

Lint and dust accumulation in the thread path of the machine, bobbin space, and tension discs can hinder free thread flow and result in breaks. Cleaning is imperative on a regular basis.

Design Density and Stitch Count

Extremely dense designs with stitches that overlap each other can strain the thread, leading to a greater chance of breaks, particularly if other conditions also exist. It is associated with typical thread break issues in embroidery machines.

Machine Speed

Sewing at too high speeds, particularly with fine threads or complex patterns, sometimes causes thread breaks.

Practical Remedies to Resolve Thread Breaks

Now that we have discussed the common reasons let us see some realistic solutions to mend thread breaks in machine embroidery remedies:

Re-thread Carefully

The first thing you should do whenever thread breaks is to re-thread your machine completely, exactly as per your machine manual. Make sure that the thread goes through all guides and tension discs in the proper order.

Adjust Thread Tension

Play with the tension settings of your machine. The automatic setting is a good place to start with, but you might have to tinker depending on your fabric and thread. Practice on test fabric until you get perfectly balanced stitches.

Use Quality Thread

Use high-quality embroidery thread suited to your fabric and design.

Choose the Right Needle

Use a needle type and size suitable for your fabric and thread weight. Microtex needles are suitable for dense weaves, and ballpoint needles for knits. Replace bent or dull needles at once.

Check your Bobbin

Keep your bobbin evenly wound and installed properly. Clean the bobbin case regularly and set the tension if needed (check your machine manual).

Re-hoop Tightly

Make sure your fabric is tight and well hooped so that it will not shift during stitching. Use a stabilizer suitable to your fabric and design.

Clean Your Machine Regularly

Remove lint and dust from the thread path, bobbin space, and tension discs using a small brush. Consult your machine manual to learn how to clean your machine.

Make Design Adjustments

If you always have thread break issues on embroidery machines with a specific design, you may need to thicken it or divide it into smaller sections.

Slowing Down Stitching

If embroidering with fine threads or complex patterns, experiment with reducing your machine's stitch speed.

Preventive Tips to Reduce Thread Breaks

Prevention is better than cure! The following are tips to avoid thread breaks in machine embroidery:

Use your needle type and size according to your fabric and thread.

Thread your machine properly and double-check the thread path.

Keep your thread tension proper and balanced.

Wind your bobbins evenly and thread them properly.

Hoop your fabric tightly using the proper stabilizer.

Clean and service your embroidery machine frequently.

Take the design density into account and alter settings or the design itself as necessary.

Try not to stitch at too high a speed, particularly for detail work.

Utilize a thread net or spool cap to assist in regulating thread unwinding.

Always utilize good-quality embroidery thread.

Conclusion

Dealing with thread breaks for machine embroidery may be frustrating. Nevertheless, you can minimize the frequency of thread breaks by grasping the widespread causes and incorporating these thread-break solutions for domestic embroidery machines as well as future endeavors. Troubleshoot thoroughly, beginning from the simplest measures such as re-threading and tensioning your thread. By keeping an eye on your supplies, machine upkeep, and skill, you'll be halfway to smoother, more pleasant embroidery projects. If you are still experiencing constant thread break troubleshooting for beginning embroiderers or require specialist guidance on digitizing for maximum stitch quality. Let DigitizingUSA help you create flawless embroidery. Contact our experts for professional digitizing services today and take your embroidery to the next level!

Reach to us for Professional Digitizing Services

Are you still struggling with constant thread breakage? For professional guidance on digitizing embroidery that reduces stitch problems and more advice on obtaining perfect stitch quality, contact the expert team of DigitizingUSA for professional digitizing services today.

Frequently Asked Questions

Why does my embroidery machine keep breaking the thread?

There can be many reasons, including incorrect thread tension, a damaged needle, lint buildup in the machine, or using low-quality thread.

What is the best way to adjust thread tension to avoid breaks?

Begin on your machine's built-in tension setting and tweak slowly, as required. Check on scraps first. Well-balanced tension will reveal identical even stitches at both your top and bottom fabrics.

Can an embroidery design cause thread breaks?

Some designs, having huge density levels of minute stitching, create very high levels of tension and put huge forces into the threads to the extent of high-breakability. Reduce the design stitch density or section breakdown accordingly.

How often should I clean my embroidery machine to prevent thread breaks?

You should clean your machine after every few projects or when you notice lint buildup. Regular cleaning helps ensure smooth thread flow.

What type of needle do I use to reduce thread breaks?

Select a needle type and size suitable for your thread and fabric. Fine needles such as microtex work well with closely woven fabrics, while ballpoint needles work better with knits. Replace damaged needles at once.